Services We Provide

Services

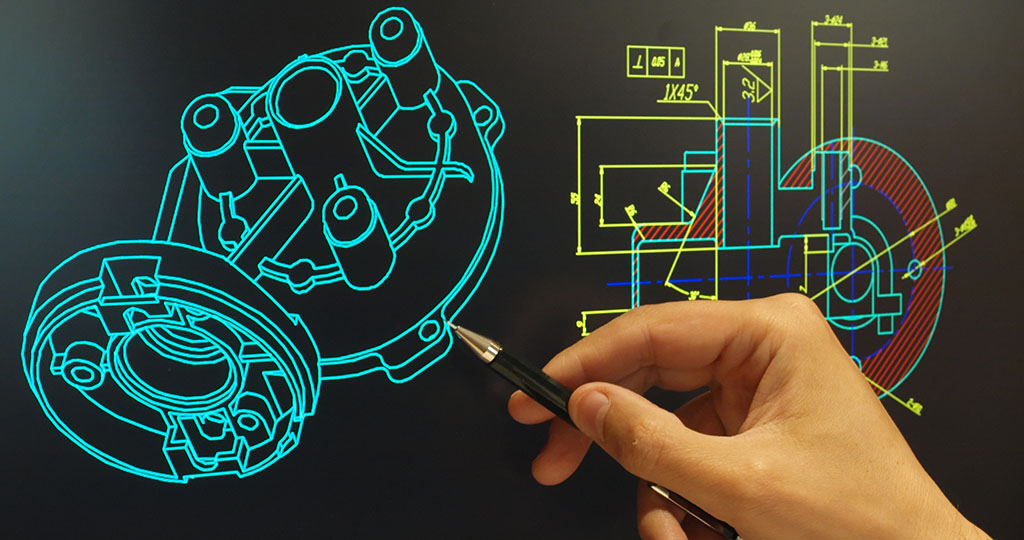

Prototype and Designing

At Swastik Foundry, we integrate advanced CAD-CAM (Computer-Aided Design & Manufacturing) technologies into our iron casting and machining processes to ensure unmatched precision, efficiency, and quality. Our in-house design team works closely with clients to transform ideas or technical drawings into highly accurate 3D models and machine-ready toolpaths. Additionally, we offer precise laser marking services to permanently imprint part numbers, logos, or custom information on components, ensuring traceability, branding, and enhanced product identification.

Casting

At Swastik Industries, we specialize in a wide range of high-quality metal casting solutions tailored to meet the diverse needs of our clients across various industries. Our state-of-the-art facilities and skilled team ensure precision, consistency, and reliability in every casting project we undertake.

We offer the following casting services:

CI (Cast Iron) Casting: Durable and cost-effective, ideal for components requiring excellent wear resistance and machinability.

SGI (Spheroidal Graphite Iron) Casting: Also known as ductile iron, offering superior strength, toughness, and impact resistance compared to regular cast iron.

MS (Mild Steel) Casting: Known for its weldability and strength, used extensively in industrial machinery and structural applications.

Aluminium Casting: Lightweight, corrosion-resistant, and highly versatile, suitable for automotive, aerospace, and consumer product components.

Non-Ferrous Metal Casting: Including brass, bronze, and other alloys, providing exceptional resistance to corrosion and excellent electrical/thermal conductivity.

Our casting processes are backed by strict quality control, in-house pattern making, advanced CAD-CAM design, and optional laser marking for component traceability and branding. We work closely with our clients from concept to production, delivering castings that meet the highest standards of precision and performance.

Machining Facility

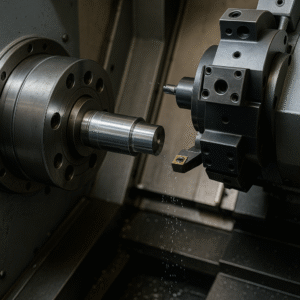

CNC Turning Machine

A CNC turning machine works by rotating a workpiece against a stationary cutting tool to remove material and shape it into the desired form. Controlled by computer programs, it follows precise instructions to perform operations like facing, threading, and grooving. The rotating workpiece spins on a chuck while the cutting tool moves along multiple axes to create cylindrical parts with high accuracy and repeatability.

VMC Turning Machine

A VMC (Vertical Machining Center) is a CNC machine where the cutting tool moves vertically while the workpiece is fixed on a horizontal table. It operates by precisely controlling the tool’s movement along multiple axes (X, Y, and Z) to perform milling, drilling, and tapping on metal or other materials. The vertical spindle allows easy tool changes and high-precision machining of complex shapes with efficient chip removal.

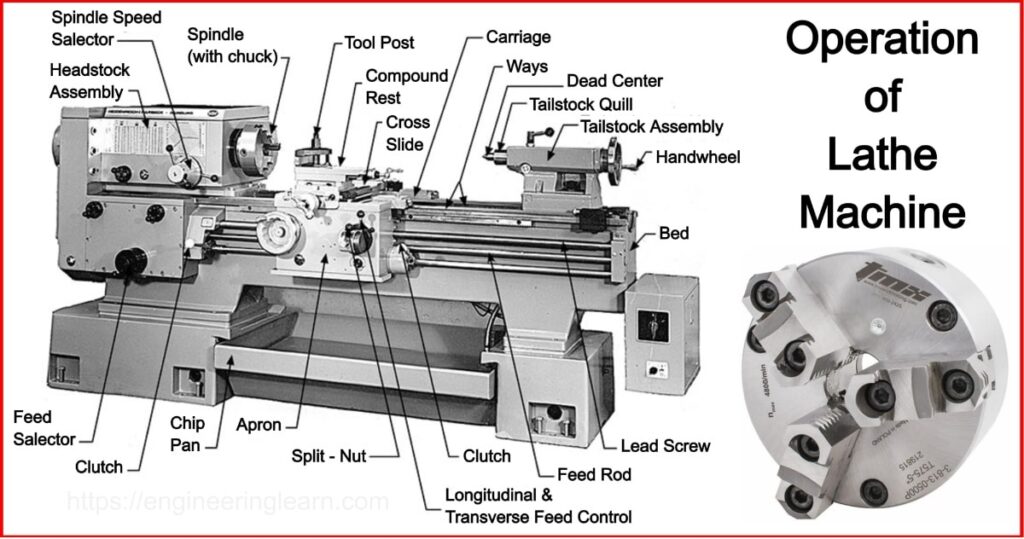

Lathe Machine:

At Swastik Industries, the lathe machine is primarily used for shaping and cutting metal or other materials. The workpiece is rotated at high speed while various cutting tools shape it into the desired form. This process allows for precise turning, threading, and drilling, making it essential for producing accurate cylindrical parts and components with smooth finishes.

Cylindrical Grinding Machine:

The cylindrical grinding machine at Swastik Industries is used to achieve a high level of precision on the external and internal surfaces of cylindrical parts. It works by rotating the workpiece against a grinding wheel, removing minute amounts of material to create a smooth, uniform surface. This ensures tight tolerances and enhances the fitting and performance of the components.

Surface Grinding Machine:

Swastik Industries employs surface grinding machines to produce flat and smooth surfaces on various components. This machine uses a rotating abrasive wheel to remove material from the surface of a workpiece, resulting in a highly accurate and polished finish. Surface grinding is crucial for improving the stability and proper assembly of parts in the manufacturing process.

Milling Machine:

Swastik Industries uses milling machines to perform precise cutting and shaping of metal or other materials. In this process, a rotating multi-toothed cutter removes material from the workpiece to create complex shapes, slots, and surfaces. Milling is highly versatile and allows the production of flat surfaces, gears, and intricate parts with accurate dimensions, making it essential for customized manufacturing needs.

Cylindrical Broaching Machine:

The cylindrical broaching machine at Swastik Industries is used for finishing and shaping internal and external cylindrical surfaces with high precision. It works by pulling or pushing a broach tool with progressively larger teeth through or over the workpiece to remove material in a controlled manner. This method is especially useful for creating precise keyways, splines, and other internal profiles that require smooth finishes and tight tolerances.

Drilling Machine:

Swastik Industries utilizes drilling machines to create accurate holes in various components. The drilling process involves rotating a drill bit that cuts into the workpiece to produce holes of different diameters and depths as per design specifications. Drilling is fundamental in manufacturing for assembly purposes and is often combined with other machining operations to produce finished products.